ACO polyethylene moulded plastic pits are lightweight, easy to cut and feature a ribbed construction for strength and durability.

Recommended for light-duty applications, these pits are robust, cost-effective and versatile.

Strength and structural performance

Polyethylene pits provide a practical solution for projects requiring reliable underground cable management without the weight and handling constraints associated with rigid or concrete enclosures.

Each plastic pit is designed to maintain structural integrity during installation and throughout its service life, particularly in locations where frequent access to cables, conduits or jointing spaces is required. The ribbed wall profile enhances stiffness under soil loading and supports consistent performance in variable ground conditions.

Installation versatility

The range includes multiple pit sizes, from compact options suited for simple cable drawing through to deeper and larger sizes for more complex uses. Sidewalls can be cut to accommodate conduit entries, allowing the enclosure to adapt to different cable routes as needed.

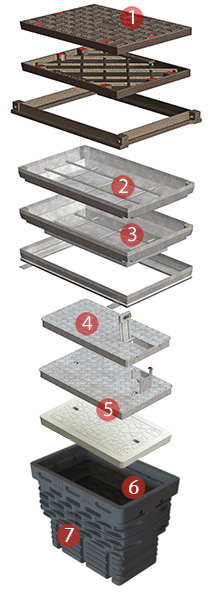

These plastic pits are enclosed with a choice of lids or access covers, manufactured from iron, steel, concrete or polymer concrete options to suit the required load class, security level and surface finish. Circular pits may also be available for niche areas such as traffic signal applications.

Compatibility with project requirements

Polyethylene pits are suited to projects where light cable enclosures are required without the need for heavy lifting equipment. Typical applications include electrical and communication networks routed through landscaped areas, footpaths or other locations with limited vehicle loading. Selection can be refined based on the required lid material type, level of security, load class and conduit configuration

Project enquiries

ACO provides expert services to support the correct selection of cable pits, access covers and related components. For technical support or project-specific guidance, contact the team today.

Polyethylene pits - features & benefits

| Ductile iron Rhinocast® solid top cover (AS 3996 Class B) AS/NZS 4586 slip resistance rating: R10 Ductile iron Rhinocast® recessed cover (AS 3996 Class B) |

|

| Steel Urbanfil® recessed cover (AS 3996 Class B) | |

| Steel Pavermate® recessed cover (AS 3996 Class B) | |

| Steel lid (AS 3996 Class B) AS/NZS 4586 slip resistance rating: R10. IP4X (AS 60529) protection against ingress of foreign objects if fitted with universal plug. If locking lid is required, contact ACO. | |

| Polymer concrete or cement concrete lid (AS 3996 Class A) AS/NZS 4586 slip resistance rating: up to R10. IP4X (AS 60529) protection against ingress of foreign objects if fitted with universal plug | |

| Strong and versatile. Continuous ribbed wall design for maximum wall strength and easy to handle. Pit walls contain cut-offs to alter the depth of the pit. | |

| Holesaw guides for conduit entry - holes can be cut anywhere on sidewalls. The maximum number of holes recommended per pit is limited by conduit quantity and size. For more information, contact ACO |

Polyethylene pits - range parts list

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 520 | 240 | 400 | 600 | ||||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 660 | 290 | 575 | 775 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 565 | 335 | 530 | 830 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 715 | 410 | 800 | 1100 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 715 | 465 | 635 | 935 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 715 | 465 | 635 | 935 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 1380 | 565 | 670 | 970 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 1020 | 565 | 1145 | 1545 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 1380 | 565 | 890 | 1290 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 1380 | 565 | 890 | 1290 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 2035 | 565 | 890 | contact ACO | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 540 | 295 | 455 | contact ACO | ||||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 430 diameter | 606 | 744 | Contact ACO | ||||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 560 | 560 | 505 | 635 | Info | Info | ||

| Nominal opening (mm) | Nominal depth (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | No Riser | 1 Riser | Pit with Lid |

Pit with Riser & Lid |

Pit with Access Cover |

Pit with Riser & Access Cover |

| 710 | 710 | 660 | 960 | Info | Info | ||

| Part No | Depth (mm) | Weight (kg) | JPG | DWG | |

|---|---|---|---|---|---|

| Type 77 polyethylene pit | 76344 | 655 | 13 | ||

| Type 77 polymer concrete riser (adds 300mm to pit depth) | 76368 | 350 | 47 |

| Part No | Weight (kg) | JPG | |

|---|---|---|---|

| Brass plate - Electricity | 77416 | 0.05 | |

| Brass plate - Communications | 77402 | 0.05 | |

| Brass plate - Gas | 77420 | 0.05 |